|

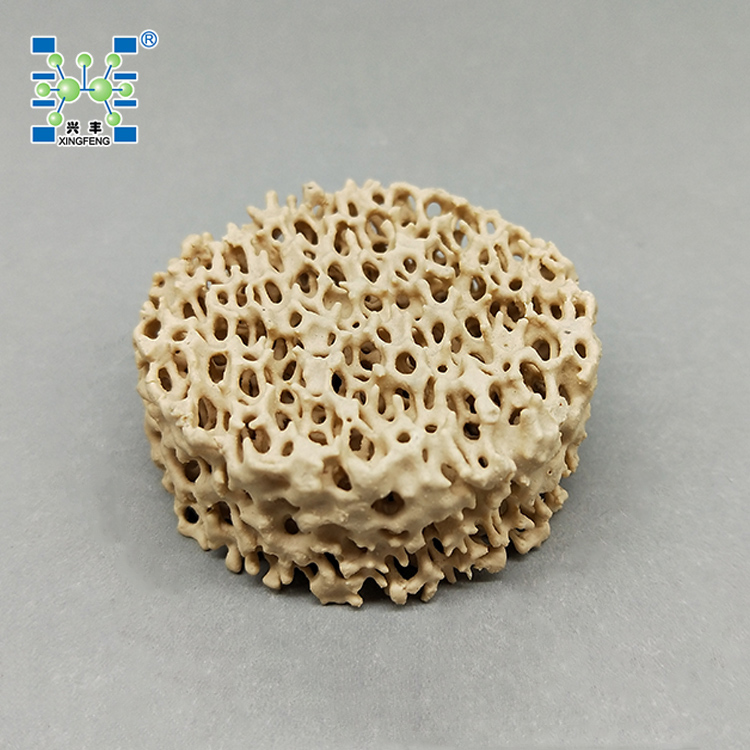

Material: Zirconia

Color: Yellow

Pore Density: 8 ppi - 60 ppi

Porosity: 80-90%

It’s very important to choose and design filter model & filter seat correctly according to casting types and pouring weight. The general principle is that the whole gating system should be a system without pressure to ensure that the molten metal liquid filling mould smoothly. Ratio of the sectional area will be the main point.

F sprue:F filter front-end:F filter back-end:F runner:F ingate = 1:4:1.75:1.1:1.2

Physical and Chemical Properties

|

Material |

Zirconia |

|

Color |

Yellow |

|

Pore Density |

8-60ppi |

|

Porosity |

80-90% |

|

Refractoriness |

≤1700℃ |

|

Bending Strength |

>1.0Mpa |

|

Compression Strength |

>1.2Mpa |

|

Volume-weight |

0.9-1.5 g/cm3 |

|

Thermal shock resistance |

6times/1100℃ |

|

Application |

High melting point metal alloys like Steel, Alloy Steel, Stainless Steel etc |

Specification for Zirconia Foam Filter

|

Dimension(mm) |

Zirconia Foam Filter |

|

|

Pouring Rate(kg) |

Filtration Capacity(kg) |

|

|

50×50×22 |

3~5 |

30 |

|

50×75×22 |

4~6 |

40 |

|

75×75×22 |

7~12 |

60 |

|

75×100×22 |

8~15 |

80 |

|

100×100×22 |

14~20 |

100 |

|

Ф50×22 |

2~6 |

18 |

|

Ф80×22 |

6~10 |

50 |

|

Ф90×22 |

8~16 |

70 |