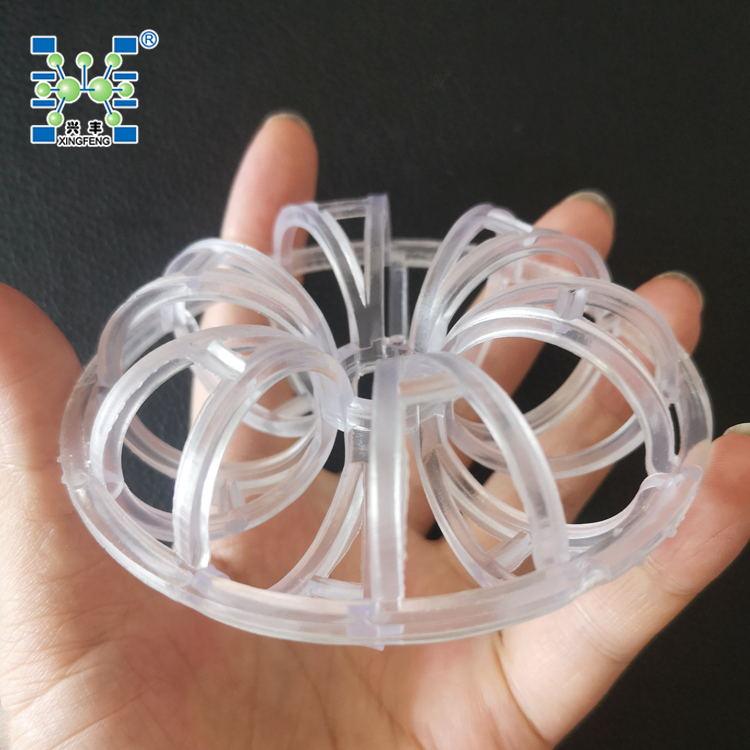

Exhaust gas absorption tower with Coster rosette packing PP polypropylene special thorn Taylor rosette (referred to as: thorn rosette packing/Taylor rosette packing) The packing is a packing invented by Teller.A.j. in the United States in 1954. It is composed of 12 small rings A large oblate sphere formed by radial arrangement, there are many small thorns on the outer ring and ribs, the small thorns can increase the specific surface area of the filler itself, and the mass transfer efficiency will be much improved, it is very similar to a coil spring A sphere that is wound end to end has become a serialized product.

The main features of TELLERETTE packing (referred to as: thorn rosette packing/thorn rosette packing) are that the packing has a large porosity, is not easy to be blocked, and has the advantages of large flux and low resistance. It can have a higher liquid stagnation amount, which can make the liquid residence time in the tower longer, thereby increasing the gas-liquid contact time and improving the efficiency. Tepper rosette packing has the characteristics of large porosity, low pressure drop and mass transfer unit height, high flooding point, sufficient vapor-liquid contact, small specific gravity, and high mass transfer efficiency.

Customizable material:

Users can choose different materials according to the conditions of use in the tower (such as temperature, pressure, medium, etc.): HDPE Trari ring , PFA Trari ring , polypropylene (PP) TTeller ring, RPP (glass reinforced polypropylene) Teller ring, polyvinyl chloride (PVC) Teller ring, chlorinated polyvinyl chloride (CPVC) Teller ring, polyvinylidene fluoride (PVDF) Teller ring and other plastic Teller ringfillers.

The use temperature of rosette packing in various media is 60-150 degrees Celsius, and it is mostly used in gas washing and purification towers.

The application of waste gas absorption tower not only contributes to environmental protection, but also saves a lot of energy for enterprises. The waste gas absorption tower uses PP Coster rosette packing to create higher value. The exhaust gas first enters the falling film collector through the exhaust pipe for cooling and falling film absorption to produce acid. The dilute acid liquid recovered by the falling film collector enters the liquid storage tank for recovery through the drain pipe, and the unabsorbed exhaust gas enters the primary absorption tower. The dilute acid liquid recovered by the primary absorption tower enters the liquid storage tank of the tower, and the unabsorbed tail gas enters the secondary absorption tower again. A small amount of exhaust gas enters the vacuum pump, the liquid recovered by the vacuum pump enters the body liquid storage tank, and the exhaust gas that reaches the standard after being absorbed by the vacuum pump is discharged through the exhaust pipe. In the acid-making reaction process, the generated low-concentration dilute acid solution participates in the acid circulation reaction, and the dilute acid solution prepared in the subsequent process is used to supplement the circulating liquid reduced in the previous process. After the concentration reaches the technological requirements, Centralized storage. This process completes the process of acid tail gas recovery. This series of equipment can be automatically controlled to realize unmanned management mode.